Manual Plastic Diaphragm Valves

Type-14 True Union Diaphragm Valve (1/2" – 2")

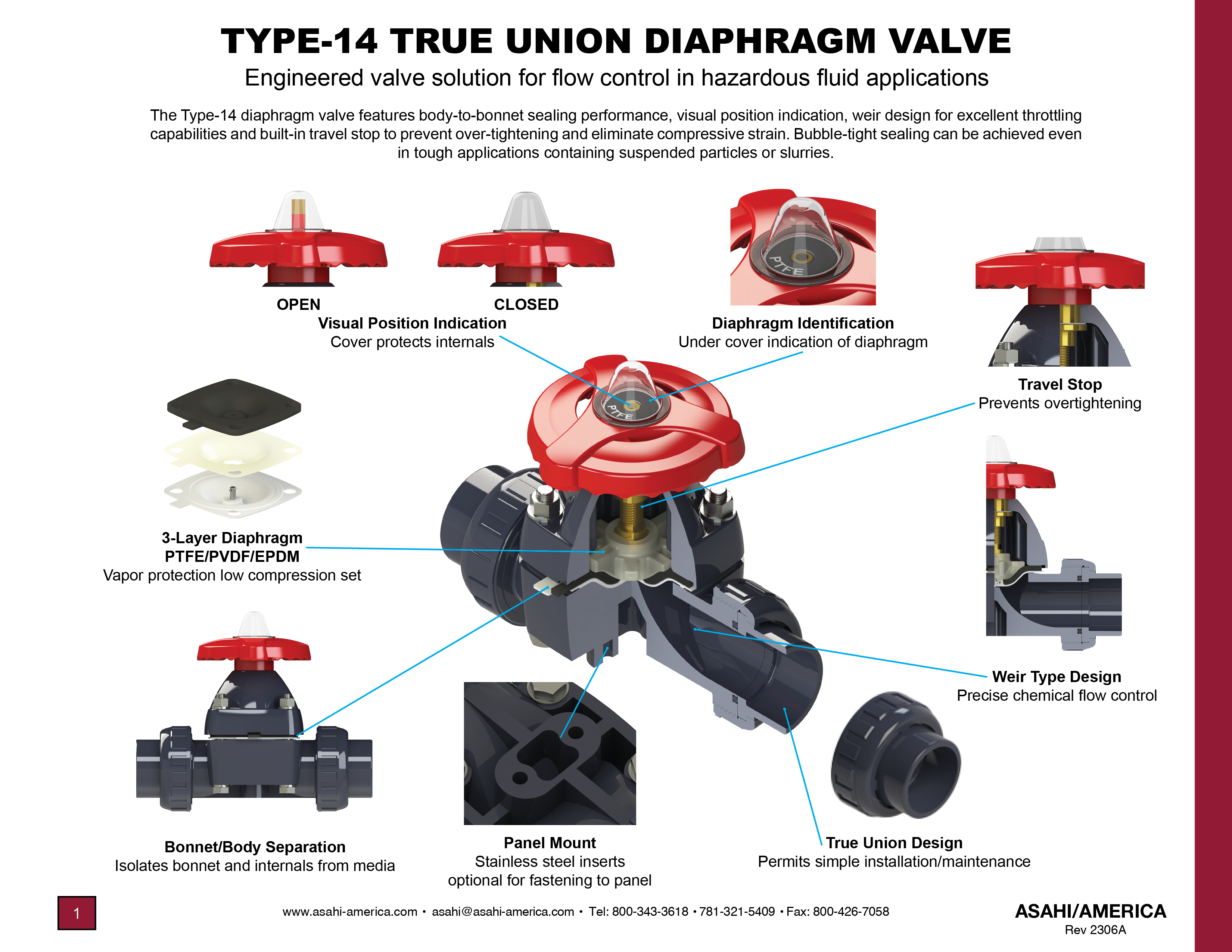

The type-14 diaphragm valve has been specified with confidence since 2002. Design features include industry-leading body-to-bonnet sealing performance isolating the bonnet components from the media, high visibility position indication with built-in travel stop providing visual confirmation while minimizing compressive strain across the diaphragm, and smooth ergonomic handle operation. Bubble-tight sealing can be achieved even in tough applications containing suspended particles or slurries. Controlled flow characteristics are achieved by way of an internal weir design, requiring fluid to flow over the raised center section of the body where the body and diaphragm meet. The molded thermoplastic valve body diaphragm and end connector O-rings are the only components in contact with the media.

Asahi's type-14 diaphragm valve features a three-layer EPDM/PVDF/PTFE diaphragm providing a gas barrier protecting the bonnet internals from aggressive off-gassing chemicals such as sodium hypochlorite. The Type-14 true-union diaphragm valve provides union end connections for simplified installation and maintenance. End connector O-rings are matched to diaphragm materials for ultimate chemical compatibility.

For maximum corrosion resistance, the type-14 diaphragm valve's body and bonnet are manufactured from solid thermoplastic materials. The type-14 diaphragm valve can be pneumatically or electrically actuated.

Resources

Type-14 flanged diaphragm valve. Download the cut sheet here.

Click here to download our newest data sheet on Type-14 Diaphragm Valve for Sodium Hypochlorite

Data Sheets

- Datasheet - Type-14 True Union Diaphragm Valve

- Datasheet - Type-14 Diaphragm Valve for Sodium Hypochlorite

Specifications